Scenario 5: Mechanical-Electro (ME) Audit Stages

Mechanical-Electro, better known as ME, is an American company that provides mechanical and electrical services in China. Their services range from air-conditioning systems, ventilation systems, plumbing, to installation of electrical equipment in automobile plants, electronic manufacturing facilities, and food processing plants.

Due to the fierce competition from local Chinese companies and failing to meet customer requirements, ME's revenue dropped significantly. In addition, customers' trust and confidence in the company decreased, and the reputation of the company was damaged.

In light of these developments, the top management of ME decided to implement a quality management system (QMS) based on ISO 9001. After having an effective QMS in place for over a year, they applied for a certification audit.

A team of four auditors was appointed for the audit, including Li Na as the audit team leader. Initially, the audit team conducted a general review of ME's documents, including the quality policy, operational procedures, inventory lists, QMS scope, process documentation, training records, and previous audit reports.

Li Na stated that this would allow the team to maintain a systematic and structured approach to gathering documents for all audit stages. While reviewing the documented information, the team observed some minor issues but did not identify any major nonconformities. Therefore, Li Na claimed that it was not necessary to prepare a report or conduct a meeting with ME's representatives at that stage of the audit. She stated that all areas of concern would be discussed in the next phase of the audit.

Following the on-site activities and the opening meeting with ME's top management, the audit team structured an audit test plan to verify whether ME's QMS conformed to Clause 8.2.1 (Customer Communication) of ISO 9001.

To do so, they gathered information through group interviews and sampling. Li Na conducted interviews with departmental managers in the first group and then with top management. In addition, she chose a sampling method that sufficiently represented customer complaints from both areas of ME' s operations.

The team members were responsible for the sampling procedure. They selected a sample size of 4 out of

45 customer complaints received weekly for electrical services and 2 out of 10 complaints for mechanical services.

Afterward, the audit team evaluated the evidence against the audit criteria and generated the audit findings.

Which stages of the audit were performed?

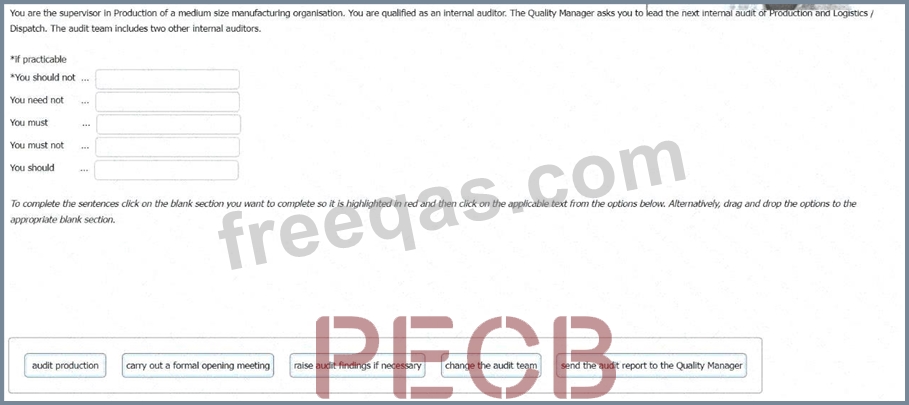

You are the supervisor in Production of a medium size manufacturing organisation. You are qualified as an internal auditor. The Quality Manager asks you to lead the next internal audit of Production and Logistics Dispatch. The audit team includes two other internal auditors.

Scenario 5: Mechanical-Electro (ME) Audit Stages

Mechanical-Electro, better known as ME, is an American company that provides mechanical and electrical services in China. Their services range from air-conditioning systems, ventilation systems, plumbing, to installation of electrical equipment in automobile plants, electronic manufacturing facilities, and food processing plants.

Due to the fierce competition from local Chinese companies and failing to meet customer requirements, ME's revenue dropped significantly. In addition, customers' trust and confidence in the company decreased, and the reputation of the company was damaged.

In light of these developments, the top management of ME decided to implement a quality management system (QMS) based on ISO 9001. After having an effective QMS in place for over a year, they applied for a certification audit.

A team of four auditors was appointed for the audit, including Li Na as the audit team leader. Initially, the audit team conducted a general review of ME's documents, including the quality policy, operational procedures, inventory lists, QMS scope, process documentation, training records, and previous audit reports.

Li Na stated that this would allow the team to maintain a systematic and structured approach to gathering documents for all audit stages. While reviewing the documented information, the team observed some minor issues but did not identify any major nonconformities. Therefore, Li Na claimed that it was not necessary to prepare a report or conduct a meeting with ME's representatives at that stage of the audit. She stated that all areas of concern would be discussed in the next phase of the audit.

Following the on-site activities and the opening meeting with ME's top management, the audit team structured an audit test plan to verify whether ME's QMS conformed to Clause 8.2.1 (Customer Communication) of ISO 9001.

To do so, they gathered information through group interviews and sampling. Li Na conducted interviews with departmental managers in the first group and then with top management. In addition, she chose a sampling method that sufficiently represented customer complaints from both areas of ME' s operations.

The team members were responsible for the sampling procedure. They selected a sample size of 4 out of

45 customer complaints received weekly for electrical services and 2 out of 10 complaints for mechanical services.

Afterward, the audit team evaluated the evidence against the audit criteria and generated the audit findings.

After reviewing the documented information, Li Na claimed that it was not necessary to report the minor nonconformities that were identified; instead, they would be discussed in the next audit phase. Is this acceptable?

Which quality management principle does an organization fulfill when it assesses risks, consequences, and impacts before taking action?

Scenario 6: Davis Clinic (DC) is an American medical center focused on integrated health care. Since its establishment DC was committed to providing qualitative services for its clients, which is the reason why the company decided to implement a quality management system (QMS) based on ISO 9001. After a year of having an active QMS in place, DC applied for a certification audit.

A team of five auditors, from a well-known certification body, was selected to conduct the audit. Eva was appointed as the audit team leader. After three days of auditing, the team gathered to review and examine their findings. They also discussed the audit findings with DC's top management and then drafted the audit conclusions.

In the closing meeting, which was held between the audit team and the top management of DC. Eva presented two nonconformities that were detected during the audit. Eva stated that the company did not retain documented information regarding its outsourced services for an analysis laboratory and regarding the conducted management reviews. During the closing meeting, the audit team required from DCs top management to come up with corrective action plans within two weeks. Although the top management did not agree with the audit findings, the audit team insisted that the auditee must submit corrective actions within the given time frame in order for the audit activities to continue.

Once the action plans were evaluated, the audit team began preparing the audit report. Eva required from the team to provide accurate descriptions of the audit findings and the audit conclusions. The report was then distributed to all the interested parties involved in the audit, including the certification body Based on the report, the certification body together with Eva, as the audit team leader, made the certification decision.

Based on the scenario above, answer the following question:

According to Scenario 6, the audit team required DC's top management to submit corrective action plans within two weeks. Is this action acceptable?

Enter your email address to download PECB.ISO-9001-Lead-Auditor.v2025-11-29.q118 Dumps